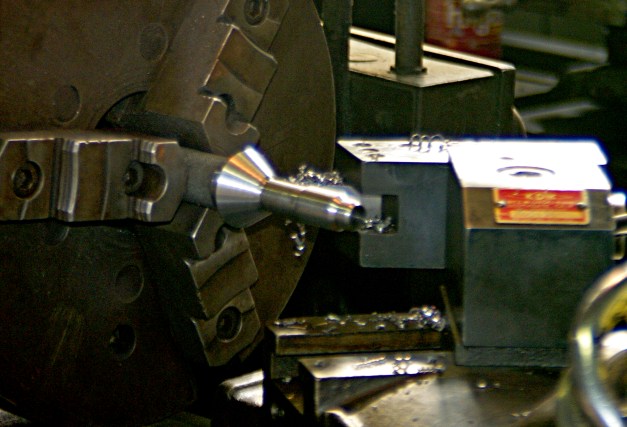

I am 86 years old. I have Parkinson’s and am not able to work as a machinist any longer. I am no longer the ‘the old machinist’ in reality and my friends at O.E.R.M. are trying hard to soften the impact this fact of life is having on me. Brian, a very good friend, comes to my home from time to time and we go the museum for a day of work. Well, what really happens is I sit and talk while Brian works. I had been ‘teaching’ Brian some of the ‘things’ I had learned as a volunteer machinist at O.E.R.M. over the past twenty or so years until I was forced to quit my active participation. I can still talk and be understood most of the time, so we do OK. My other friends at O.E.R.M still seek my advice on ‘how do we do that’ issues. I am very grateful that I have such good friends. What prompted me to write this little piece is that I today I received a notice that I had a new follower of this Blog. It occurred to me that I will be unable to recount any new activities in the machine shop, but I will, from time to time, write about my past activities in the shop world. Hang in there new friend, I’m still kicking.

‘The Old Machinist’